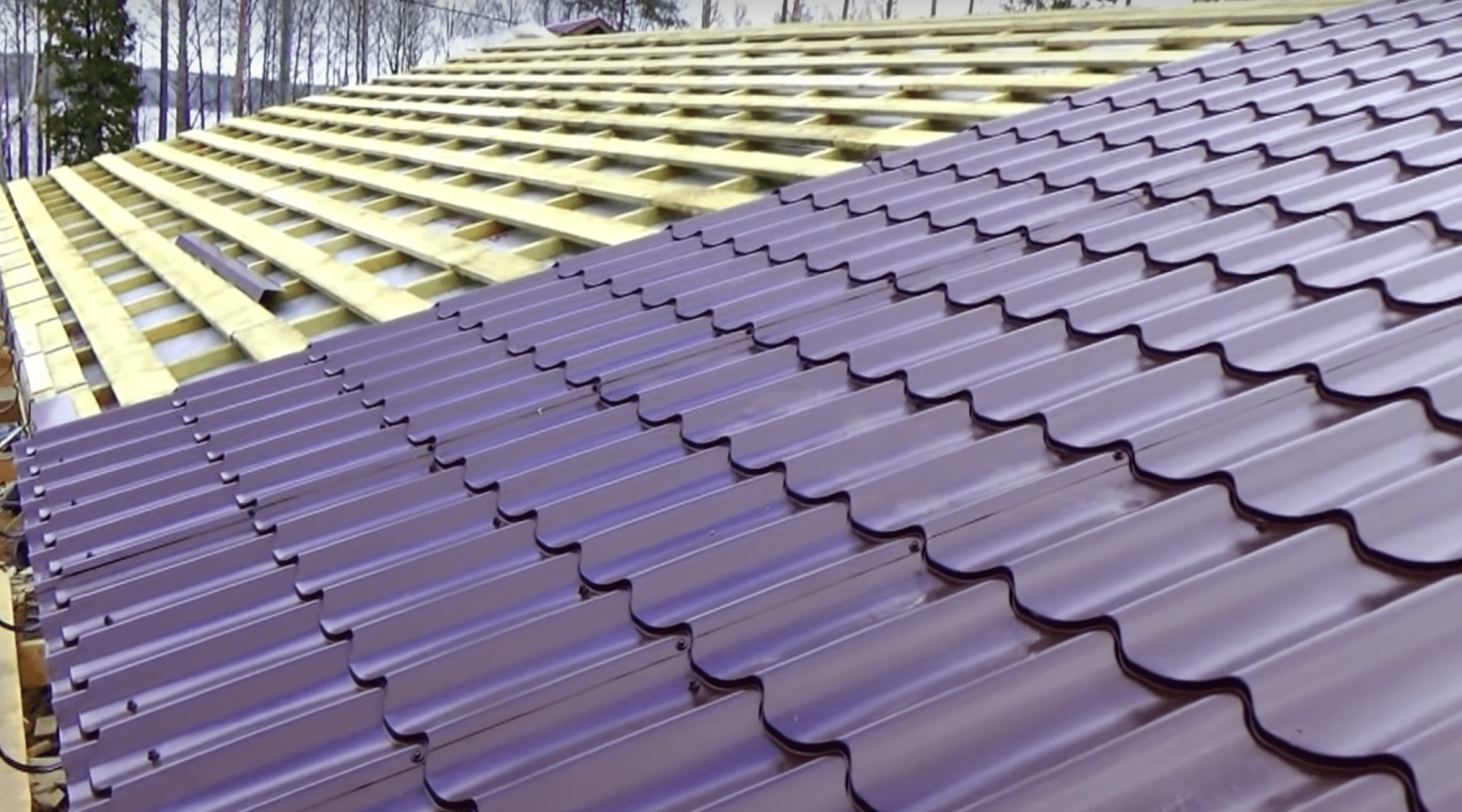

DIY metal tile installation: preparation for the process

The material is usually laid on a flat base in the form of a metal tile batten. For this design, a dry coniferous board is used, which is installed at a certain interval, taking into account the load on the object. The batten pitch depends on the profile of the metal tile and is usually equal to the length of one wave.

The boards are fixed to the rafters using nails or galvanized roofing screws with a length of 90 to 100 mm. It is necessary to ensure that each board rests on at least three rafters. A distance of 10-15 mm is left between the boards to create conditions for ventilation and compensation for thermal expansion.

Metal tile installation technology

.jpg)

Laying this material when arranging a roof involves the implementation of four basic stages:

- Stage one. Laying the starting strip. It is attached to the first board of the crate using nails with an anti-corrosion coating.

- Stage two. Laying the first sheet. It is fixed from the bottom up, and each subsequent sheet is mounted in the overlay on the previous one.

- Stage three. Roof installation. The work uses screws or self-tapping screws that have sealing heads.

- Stage four. Installation of the ridge, valley, strips and other elements for connecting the roof. They are laid after installing all the sheets, providing for fixation using self-tapping screws.

At the end of the roofing work, it is necessary to make sure that the material does not swell, there are waves and other defects.

What are the mistakes when installing metal tiles?

.jpg)

To avoid defects during work, it is necessary to pay attention to the installation features. Failure to comply with the technology can lead to a violation of tightness, as a result of which condensate appears under the structure. The most typical mistakes of roofers in this case are:

- lack of vapor barrier and waterproofing of the roof, as a result of which condensate appears on the surface, and moisture in the room;

- incorrectly made marking at the initial stage and inaccurate cutting of metal tiles;

- failure to observe the distance for fixing the sheets.

All this leads to a loss of operational characteristics and a reduction in the service life of the finished coating.

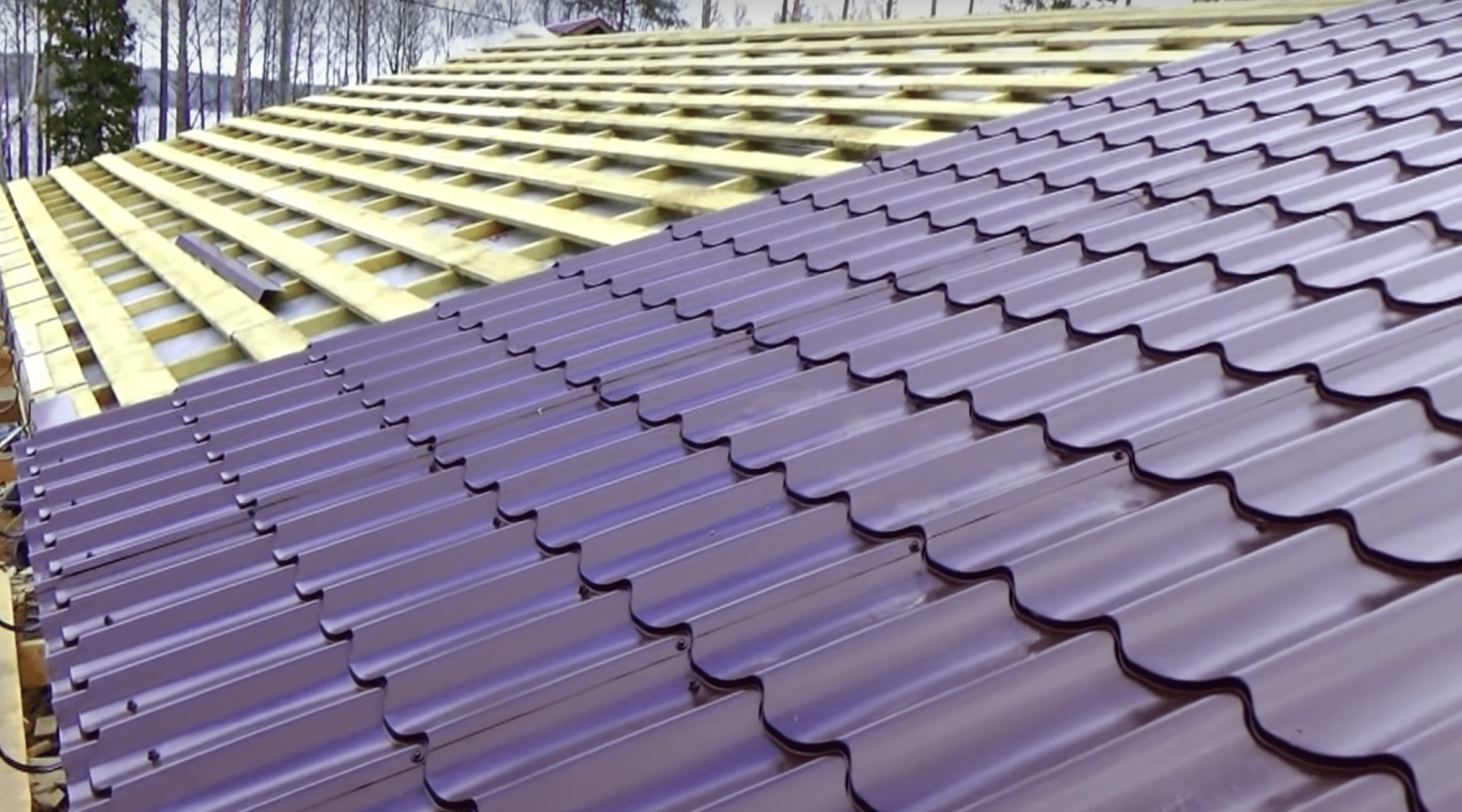

Metal tiles or corrugated board: which is better?

Metal roofing tiles are made of pressed sheet metal, resembling ceramic or concrete tiles. They are easy to install, creating the illusion of tiles. The main advantages of this material are its low weight and strength, and the ability to easily replace damaged elements if necessary. Users also often note the variety of colors, which allows everyone to choose the design they want.

As for corrugated board, such a metal roof is somewhat inferior to metal tiles in appearance, but its cost is lower. The basis of the material is sheet rolled steel, made by cold rolling. In addition to roofing, it is used to make fences, building facades and other structures.

The protective polymer coating of the surface of the products provides reliable protection against damage and is available in a variety of colors. Corrugated board can be installed on surfaces with any roof slope, but it is extremely necessary to lay an additional soundproofing layer during operation.

.jpg)

.jpg)